2026 Best Strategies for Global Sourcing Success?

In today's competitive landscape, mastering global sourcing is essential for businesses aiming for success. As John Smith, a renowned expert in global sourcing, once said, "Effective global sourcing is not just about low costs; it's about strategic partnerships." This statement encapsulates the essence of a successful sourcing strategy.

Organizations must evaluate their sourcing decisions carefully. Relying solely on cost can lead to missed opportunities for innovation and quality. Flexibility is critical. Companies should adapt their strategies to respond to market changes.

Furthermore, building lasting relationships with global suppliers is vital. Trust and communication can foster collaboration and drive mutual growth. However, obstacles such as cultural differences and time zones can complicate these interactions. Companies must navigate these challenges thoughtfully, reflecting on their approaches to global sourcing.

Key Principles for Effective Global Sourcing Strategy

In the realm of global sourcing, success hinges on a few key principles. Understanding local markets is vital. Each region has unique needs and preferences. Researching these specifics can enhance sourcing outcomes. Not every country offers the same quality or price. Sometimes, the best option may lie in an unexpected place.

Engaging with suppliers directly fosters stronger relationships. Communication is crucial. Misunderstandings can lead to costly errors. Regular interaction, even casual check-ins, builds trust. This connection may reveal hidden opportunities for improvement. Mistakes happen, and it is essential to address them quickly. Learn from these experiences to refine strategies.

Flexibility is another principle that cannot be overlooked. The global landscape is ever-changing. Factors like political instability or natural disasters can disrupt plans. Companies must adapt quickly to stay competitive. Rigid strategies often fail in turbulent times. Regularly revisiting and adjusting sourcing plans takes agility and foresight. Embracing change can lead to innovative solutions.

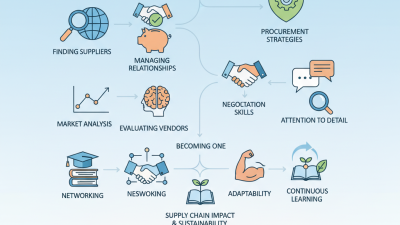

Identifying and Evaluating Global Suppliers

Identifying and evaluating global suppliers is more crucial than ever. A recent report from the Global Sourcing Institute reveals that 65% of companies face challenges in selecting reliable suppliers. This decision can impact not just costs, but overall supply chain efficiency. Evaluating suppliers requires careful attention to performance metrics, such as delivery times and quality control. Companies should prioritize data-driven analysis to avoid missteps that can lead to costly delays.

Evaluating potential suppliers involves more than just looking at price points. Transparency is key. According to a survey by Supplier Intelligence, 70% of sourcing professionals assess supplier sustainability practices. Ignoring this can result in reputational damage and missed opportunities for collaboration. Product samples and contract negotiations are also vital. Engaging directly with suppliers during the evaluation process can reveal strengths or weaknesses not evident in reports.

Beyond numerical metrics, qualitative assessments play a role. Interviews and factory visits offer insights that spreadsheets cannot. However, relying solely on gut feelings can lead to rash decisions. Many companies report regrettable outcomes due to insufficient supplier research. This illustrates the need for a balanced approach, combining quantitative data with qualitative insights. An informed strategy is essential for successful global sourcing initiatives.

2026 Best Strategies for Global Sourcing Success

This chart illustrates the effectiveness of different strategies for global sourcing success in 2026 based on various key metrics. The strategies evaluated include Supplier Diversification, Quality Control, Cost Management, Communication, and Risk Assessment.

Leveraging Technology for Enhanced Supply Chain Efficiency

In today’s global market, leveraging technology is crucial for efficient supply chain management. Recent studies show that 79% of companies consider supply chain agility as a key driver of success. Organizations are increasingly turning to digital tools to better forecast demand and manage inventory. For instance, predictive analytics can reduce excess inventory by up to 30%, saving significant costs for companies.

Moreover, integrating artificial intelligence and machine learning helps identify potential disruptions in the supply chain. A report from a leading industry analysis firm revealed that companies using AI are 3.6 times more likely to outperform their peers in supply chain efficiency. However, the transition to tech-driven models is not seamless. Many organizations struggle with data silos and inadequate technology integration, leading to inefficiencies.

Real-time tracking technologies improve visibility but require upfront investment. A study highlighted that 60% of firms face challenges in adopting these innovative solutions due to a lack of skilled personnel. As companies embrace these technologies, the need for ongoing training and support becomes apparent. Addressing these gaps is essential for capitalizing on the full potential of technological advancements in supply chain management.

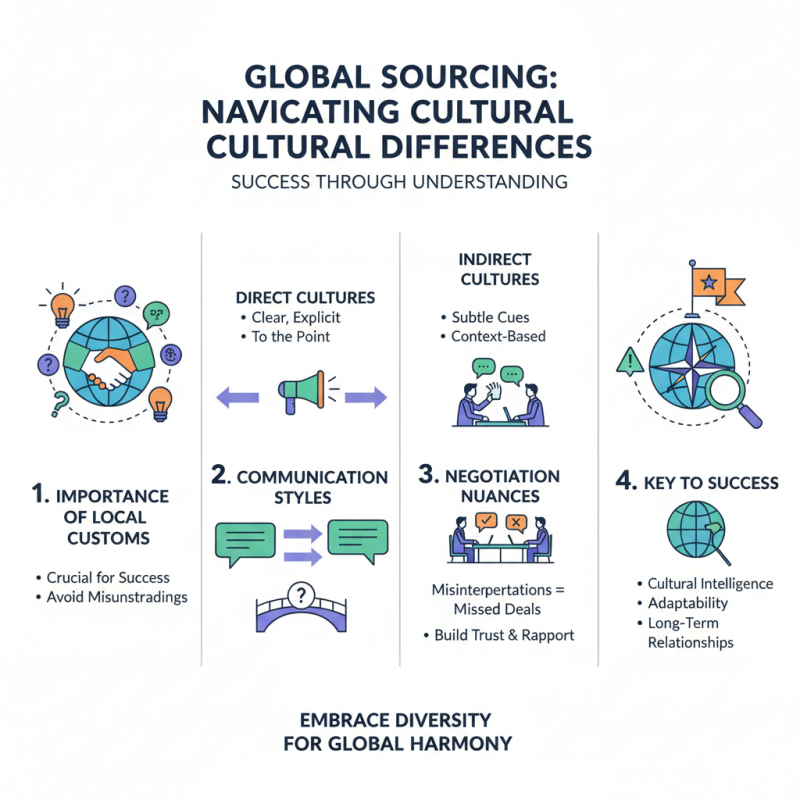

Navigating Cultural Differences in Global Sourcing

Navigating cultural differences in global sourcing is crucial for success. Understanding local customs and practices is essential. For instance, in some cultures, direct communication is valued, while in others, indirect cues are the norm. Misinterpretations can lead to misunderstandings in negotiations. It’s important to be aware of these nuances.

Building relationships takes time in many cultures. Some partners may not prioritize quick deals. Patience is necessary. Small talk can also play a big role. Engaging in casual conversations can foster trust. This is often overlooked, yet it holds significant weight. Additionally, be mindful of holiday schedules. They vary widely and can affect timelines.

Flexibility is key when working across borders. Adapt strategies based on cultural insights. Rigid approaches may lead to failure. Reflect on past experiences and learn. Mistakes happen, but they can provide valuable lessons. Acknowledge that each culture has unique strengths. Embrace these differences rather than resisting them. Such understanding can transform challenges into opportunities.

Mitigating Risks in International Supply Relationships

In today's global market, managing international supply relationships is fraught with challenges. Mitigating risks requires a proactive approach. Understanding local regulations can prevent costly mistakes. Compliance issues can arise unexpectedly. A different culture might mean different business practices. Communication gaps often lead to misunderstandings. Regularly engaging with suppliers helps strengthen ties.

Building a diversified supplier base is essential. Relying on one source can be risky. If a disruption occurs, your supply chain is at risk. Evaluate potential suppliers carefully. Don’t solely focus on price; consider reliability and quality. Look for suppliers with solid contingency plans. Have backup options in place. This can save time and resources when issues arise.

Yet, it’s not always easy to find reliable partners. Some suppliers may overpromise and underdeliver. Regular assessments can help identify trouble spots. Trust your instincts but verify results. Transparency in international dealings fosters long-term relationships. Sometimes, you must confront tough conversations. It's better to address issues head-on than let them fester. Embrace the learning curve; every setback offers valuable insight.

2026 Best Strategies for Global Sourcing Success: Mitigating Risks in International Supply Relationships

| Strategy | Description | Key Benefits | Risk Mitigation |

|---|---|---|---|

| Supplier Diversification | Engaging multiple suppliers across different regions | Reduced dependency and increased competition | Minimized regional disruption risks |

| Contractual Clarity | Establishing clear terms and conditions in contracts | Prevention of disputes and misunderstandings | Enhanced legal safeguards |

| Regular Audits | Conducting frequent assessments of suppliers | Ensures compliance and quality standards | Identifies issues before they escalate |

| Technological Integration | Using technology for real-time tracking and communication | Improved efficiency and transparency | Quick responses to supply chain disruptions |

| Cultural Training | Training employees on cultural differences | Enhanced communication and collaboration | Reduction of miscommunication issues |

Related Posts

-

Exploring the Role of a Sourcing Specialist in Sustainable Supply Chain Management

-

What Does a Sourcing Specialist Do and How to Become One?

-

Unlocking Advantages: Explore the Benefits of Best Global Sourcing for Your Business

-

The Ultimate Guide to Mastering Sourcing and Procurement Strategies for Your Business

-

How to Become a Sourcing Specialist in 2026?

-

Overcoming Challenges in Global Sourcing: Navigating Common Pitfalls